Air cooling

Fans

Fans are used when natural convection is insufficient to remove heat. Fans may be fitted to the computer case or attached to CPUs, GPUs, chipset, PSU, hard drives, or as cards plugged into an expansion slot. Common fan sizes include 40, 60, 80, 92, 120, and 140 mm. 200, 230, and 250 mm fans are sometimes used in high-performance personal computers.Performance of fans in chassis

Further information: [Chassis Plans White Paper - Cooling and Noise]

A computer has a certain resistance to air flowing through the

chassis and components. This is the sum of all the smaller impediments

to air flow, such as the inlet and outlet openings, air filters,

internal chassis, and electronic components. Fans are simple air pumps

which provide pressure to the air of the inlet side relative to the

output side. That pressure difference moves air through the chassis,

with air flowing to areas of lower pressure.Fans generally have two published specifications: free air flow and maximum differential pressure. Free air flow is the amount of air a fan will move with zero back-pressure. Maximum differential pressure is the amount of pressure a fan can generate when completely blocked. In between these two extremes are a series of corresponding measurements of flow versus pressure which is usually presented as a graph. Each fan model will have a unique curve, like the dashed curves in the adjacent illustration.

Parallel versus series installation

Fans can be installed parallel to each other, in series, or a combination of both. Parallel installation would be fans mounted side by side. Series installation would be a second fan in line with another fan such as an inlet fan and an exhaust fan. To simplify the discussion, it is assumed the fans are the same model.Parallel fans will provide double the free air flow but no additional driving pressure. Series installation, on the other hand, will double the available static pressure but not increase the free air flow rate. The adjacent illustration shows a single fan versus two fans in parallel with a maximum pressure of 0.15 inches (3.8 mm) of water and a doubled flow rate of about 72 cubic feet per minute (2.0 m3/min).

A close look at the following photo of the 1U enclosure with 7 fans will show it actually contains 14 fans with the fans mounted serially and in parallel.

Note that air flow changes as the square root of the pressure. Thus, doubling the pressure will only increase the flow 1.41 (√2) times, not twice as might be assumed. Another way of looking at this is that the pressure must go up by a factor of four to double the flow rate.

To determine flow rate through a chassis, the chassis impedance curve can be measured by imposing an arbitrary pressure at the inlet to the chassis and measuring the flow through the chassis. This requires fairly sophisticated equipment. With the chassis impedance curve (represented by the solid red and black lines on the adjacent curve) determined, the actual flow through the chassis as generated by a particular fan configuration is graphically shown where the chassis impedance curve crosses the fan curve. The slope of the chassis impedance curve is a square root function, where doubling the flow rate required four times the differential pressure.

In this particular example, adding a second fan provided marginal improvement with the flow for both configurations being approximately 27–28 cubic feet per minute (0.76–0.79 m3/min). While not shown on the plot, a second fan in series would provide slightly better performance than the parallel installation.

Temperature versus flow rate

The equation for required airflow through a chassis is

where

CFM = Cubic Feet per Minute (0.028 m3/min) Q = Heat Transferred (kW) Cp = Specific Heat of Air r = Density DT = Change in Temperature (in °F)A simple conservative rule of thumb for cooling flow requirements, discounting such effects as heat loss through the chassis walls and laminar versus turbulent flow, and accounting for the constants for Specific Heat and Density at sea level is: (Please Note It must be between sea level)

For example, a typical chassis with 500 watts of load, 130 °F (54 °C) maximum internal temperature in a 100 °F (38 °C) environment, i.e. a difference of 30 °F (17 °C):

This would be actual flow through the chassis and not the free air rating of the fan.

Piezoelectric pump

A "dual piezo cooling jet", patented by GE, uses vibrations to pump air through the device. The initial device is three millimeters thick and consists of two nickel discs that are connected on either side to a sliver of piezoelectric ceramics. An alternating current passed through the ceramic component causes it to expand and contract at up to 150 times per second so that the nickel discs act like a bellows. Contracted, the edges of the discs are pushed together and suck in hot air. Expanding brings the nickel discs together, expelling the air at high velocity.The device has no bearings and does not require a motor. It is thinner and consumes less energy than typical fans. The jet can move the same amount of air as a cooling fan twice its size while consuming half as much electricity and at lower cost.

Passive cooling

Passive heat-sink cooling involves attaching a block of machined or extruded metal to the part that needs cooling. A thermal adhesive may be used. More commonly for a personal-computer CPU, a clamp holds the heat sink directly over the chip, with a thermal grease or thermal pad spread between. This block has fins and ridges to increase its surface area. The heat conductivity of metal is much better than that of air, and it radiates heat better than the component that it is protecting (usually an integrated circuit or CPU). Fan-cooled aluminium heat sinks were originally the norm for desktop computers, but nowadays many heat sinks feature copper base-plates or are entirely made of copper.Dust buildup between the metal fins of a heat sink gradually reduces efficiency, but can be countered with a gas duster by blowing away the dust along with any other unwanted excess material.

Passive heat sinks are commonly found on older CPUs, parts that do not get very hot (such as the chipset), and low-power computers.

Usually a heat sink is attached to the integrated heat spreader (IHS), essentially a large, flat plate attached to the CPU, with conduction paste layered between. This dissipates or spreads the heat locally. Unlike a heat sink, a spreader is meant to redistribute heat, not to remove it. In addition, the IHS protects the fragile CPU.

Passive cooling involves no fan noise.

Other techniques

Liquid submersion cooling

An uncommon practice is to submerge the computer's components in a thermally, but not electrically, conductive liquid. Although rarely used for the cooling of personal computers,[7]d submersion is a routine method of cooling large power distribution components such as transformers. It is also becoming popular with data centers.[8][9] Personal computers cooled in this manner may not require either fans or pumps, and may be cooled exclusively by passive heat exchange between the computer hardware and the plastic box it is placed in.[10][11] A heat exchanger (i.e. heater core or radiator) might still be needed though, and the piping also needs to be placed correctly.[12] Extreme component density supercomputers such as the Cray-2 and Cray T90 used additional large liquid-to-chilled liquid heat exchangers for heat removal.The liquid used must have sufficiently low electrical conductivity not to interfere with the normal operation of the computer. If the liquid is somewhat electrically conductive, it may be necessary to insulate certain parts of components susceptible to electromagnetic interference, such as the CPU.[13] For these reasons, it is preferred that the liquid be dielectric.

A wide variety of liquids exist for this purpose, the most suitable being transformer oils and other specialty electrical cooling oils such as 3M Fluorinert. Non-purpose oils, including cooking, motor and silicone oils, have been successfully used for cooling personal computers.

Evaporation can pose a problem, and the liquid may require either to be regularly refilled or sealed inside the computer's enclosure. According to one company that builds and sells mineral oil submersion kits, they initially found that oil would be lost through a wicking effect up cables that were submerged in the oil. This is no longer the case, as they modified the kit.[14]

Waste heat reduction

Where powerful computers with many features are not required, less powerful computers or ones with fewer features can be used. As of 2011 a VIA EPIA motherboard with CPU typically dissipates approximately 25 watts of heat, whereas a more capable Pentium 4 motherboard and CPU typically dissipates around 140 watts. Computers can be powered with direct current from an external power supply brick which does not generate heat inside the computer case. The replacement of cathode ray tube (CRT) displays by more efficient thin-screen liquid crystal display (LCD) ones in the early twenty-first century reduces power consumption significantly.Heat-sinks

Main article: Heat sink

Heat is removed from the heat-sink by convection, to some extent by radiation, and possibly by conduction if the heat-sink is in thermal contact with, say, the metal case. Inexpensive fan-cooled aluminium heat sinks are often used on standard desktop computers. Heat-sinks with copper base-plates, or made of copper, have better thermal characteristics than aluminium. A copper heat-sink is more effective than an aluminium unit of the same size, which is relevant with regard to the high-power-consumption components used in high-performance computers.

Passive heat sinks are commonly found on: older CPUs, parts that do not dissipate much power, such as the chipset, computers with low-power processors, and equipment where silent operation is critical and fan noise unacceptable.

Usually a heat-sink is clamped to the integrated heat spreader (IHS), a flat metal plate the size of the CPU package which is part of the CPU assembly and spreads the heat locally. A thin layer of thermal compound is placed between them to compensate for surface imperfections. The spreader's primary purpose is to redistribute heat. The heat-sink fins improve its efficiency.

Several brands of DDR2 and DDR3 memory modules are fitted with a finned heatsink clipped onto the top edge of the module. The same technique is used for video cards that use a finned passive heatsink on the GPU.

Dust tends to build up in the crevices of finned heatsinks, particularly with the high airflow produced by fans. This keeps the air away from the hot component, reducing cooling effectiveness; however, removing the dust restores effectiveness.

Peltier (thermoelectric) cooling

Main article: Thermoelectric cooling

Regular Peltier cooling setup for PC's

Modern TECs use several stacked units each composed of dozens or hundreds of thermocouples laid out next to each other, which allows for a substantial amount of heat transfer. A combination of bismuth and tellurium is most commonly used for the thermocouples.

As active heat pumps which consume power, TECs can produce temperatures below ambient, impossible with passive heatsinks, radiator-cooled fluid cooling, and heatpipe HSFs.

Liquid cooling

For more details on water cooling, see water cooling.

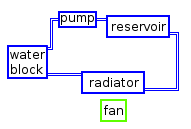

Schematic of a regular liquid cooling setup for PC's

The principle used in a typical (active) liquid cooling system for computers is identical to that used in an automobile's internal combustion engine, with the water being circulated by a water pump through a waterblock mounted on the CPU (and sometimes additional components as GPU and northbridge[17] and out to a heat exchanger, typically a radiator. The radiator is itself sometimes cooled additionally by means of a fan.[18] Besides a fan, it could possibly also be cooled by other means, such as by means of a Peltier cooler (although Peltier elements are most commonly placed directly on top of the hardware to be cooled, and the coolant is used to conduct the heat away from the hot side of the Peltier element).[19][20] Also, a coolant reservoir is often also connected to the system.[21]

Besides active liquid cooling systems, passive liquid cooling systems are also sometimes used.[22][23][24][25][26] These systems often discard a fan or a water pump, hence theoretically increasing the reliability of the system, and/or making it quieter than active systems. Downsides of these systems however are that they are much less efficient in discarding the heat and thus also need to have much more coolant -and thus a much bigger coolant reservoir- (giving more time to the coolant to cool down).

Liquids allow the transfer of more heat from the parts being cooled than air, making liquid cooling suitable for overclocking and high performance computer applications.[27] Compared to air cooling, liquid cooling is also influenced less by the ambient temperature.[citation needed] Liquid cooling's comparatively low noise-level compares favorably to that of active cooling, which can become quite noisy.

Disadvantages of liquid cooling include complexity and the potential for a coolant leak. Leaked water can damage any electronic components with which it comes into contact, and the need to test for and repair leaks makes for more complex and less reliable installations. An air-cooled heat sink is generally much simpler to build, install, and maintain than a water cooling solution,[28] although CPU specific water cooling kits can also be found, which may be just as easy to install as an air cooler. These are not limited to CPUs, however, and cooling of GPU cards is also possible.[29]

While originally limited to mainframe computers, liquid cooling has become a practice largely associated with overclocking in the form of either manufactured kits, or in the form of do-it-yourself setups assembled from individually gathered parts. The past few years have seen an increase in the popularity of liquid cooling in pre-assembled, moderate to high performance, desktop computers. Sealed ("closed-loop") systems incorporating a small pre-filled radiator, fan, and waterblock simplify the installation and maintenance of water cooling at a slight cost in cooling effectiveness relative to larger and more complex setups. Liquid cooling is typically combined with air cooling, using liquid cooling for the hottest components, such as CPUs or GPUs, while retaining the simpler and cheaper air cooling for less demanding components.

The IBM Aquasar system uses hot water cooling to achieve energy efficiency, the water being used to heat buildings as well.[30][31]

Since 2011, the effectiveness of water cooling has prompted a series of all-in-one (AIO) water cooling solutions. AIO solutions result in a much simpler to install unit, and most units have been reviewed positively from review sites.

The Danamics LMX Superleggera CPU cooler uses the liquid metal NaK to transport heat from the CPU to its cooling fins.[32]

Heat pipe

Main article: Heat pipe

A heat pipe is a hollow tube containing a heat transfer liquid. The

liquid absorbs heat and evaporates at one end of the pipe. The vapor

travels to the other (cooler) end of the tube, where it condenses,

giving up its latent heat. The liquid returns to the hot end of the tube by gravity or capillary action

and repeats the cycle. Heat pipes have a much higher effective thermal

conductivity than solid materials. For use in computers, the heat sink

on the CPU is attached to a larger radiator heat sink. Both heat sinks

are hollow, as is the attachment between them, creating one large heat

pipe that transfers heat from the CPU to the radiator, which is then

cooled using some conventional method. This method is expensive and

usually used when space is tight, as in small form-factor PCs and

laptops, or where no fan noise can be tolerated, as in audio production.

Because of the efficiency of this method of cooling, many desktop CPUs

and GPUs, as well as high end chipsets, use heat pipes in addition to

active fan-based cooling to remain within safe operating temperatures.Electrostatic air movement and corona discharge effect cooling

The cooling technology under development by Kronos and Thorn Micro Technologies employs a device called an ionic wind pump (also known as an electrostatic fluid accelerator). The basic operating principle of an ionic wind pump is corona discharge, an electrical discharge near a charged conductor caused by the ionization of the surrounding fluid (air).The principle of ionic air propulsion with corona-generated charged particles has been known almost as long as electricity itself. One of the first references to sensing moving air near a charged tube appeared some 300 years ago in a book by Francis Hauksbee and many pioneers of electricity, including Newton, Faraday, and Maxwell, studied this phenomenon. In modern times, corona discharge was utilized in various ways and applied in the photocopying industry, in some air-conditioning systems, in nitrogen lasers, and most notably in air ionizers. Kronos, which develops high efficiency corona-based air filters, attempted to adapt the technology to microprocessor cooling. With the help of N. E. Jewell-Larsen, C. P. Hsu, and A. V. Mamishev from the Department of Electrical Engineering at the University of Washington and from Intel, they created several working prototypes of a corona discharge CPU cooler, which can silently but effectively cool a modern CPU.

The corona discharge cooler developed by Kronos works in the following manner: A high electric field is created at the tip of the cathode, which is placed on one side of the CPU. The high energy potential causes the oxygen and nitrogen molecules in the air to become ionized (positively charged) and create a corona (a halo of charged particles). Placing a grounded anode at the opposite end of the CPU causes the charged ions in the corona to accelerate towards the anode, colliding with neutral air molecules on the way. During these collisions, momentum is transferred from the ionized gas to the neutral air molecules, resulting in movement of gas towards the anode.

The advantages of the corona-based cooler are obvious: it has no moving parts thereby eliminating certain reliability issues, it can effectively cool even the most advanced and demanding processors and it operates with a near-zero noise level and with moderate energy consumption.[33]

Soft cooling

Soft cooling is the practice of utilizing software to take advantage of CPU power saving technologies to minimize energy use. This is done using halt instructions to turn off or put in standby state CPU subparts that aren't being used or by underclocking the CPU. While resulting in lower total speeds, this can be very useful if overclocking a CPU to improve user experience rather than increase raw processing power, since it can prevent the need for noisier cooling. Contrary to what the term suggests, it is not a form of cooling but of reducing heat creation.Undervolting

Undervolting is a practice of running the CPU or any other component with voltages below the device specifications. An undervolted component draws less power and thus produces less heat. The ability to do this varies by manufacturer, product line, and even different production runs of the same product (as well as that of other components in the system), but processors are often specified to use voltages higher than strictly necessary. This tolerance ensures that the processor will have a higher chance of performing correctly under sub-optimal conditions, such as a lower-quality motherboard or low power supply voltages. Below a certain limit the processor will not function correctly, although undervolting too far does not typically lead to permanent hardware damage.Undervolting is used for quiet systems, as less cooling is needed because of the reduction of heat production, allowing noisy fans to be omitted. It is also used when battery charge life must be maximized.

Chip-integrated

Conventional cooling techniques all attach their “cooling” component to the outside of the computer chip package. This “attaching” technique will always exhibit some thermal resistance, reducing its effectiveness. The heat can be more efficiently and quickly removed by directly cooling the local hot spots of the chip, within the package. At these locations, power dissipation of over 300 W/cm2 (typical CPU is less than 100 W/cm2) can occur, although future systems are expected to exceed 1000 W/cm2.[34] This form of local cooling is essential to developing high power density chips. This ideology has led to the investigation of integrating cooling elements into the computer chip. Currently there are two techniques: micro-channel heat sinks, and jet impingement cooling.In micro-channel heat sinks, channels are fabricated into the silicon chip (CPU), and coolant is pumped through them. The channels are designed with very large surface area which results in large heat transfers. Heat dissipation of 3000 W/cm2 has been reported with this technique.[35] The heat dissipation can be further increased if two-phase flow cooling is applied. Unfortunately, the system requires large pressure drops, due to the small channels, and the heat flux is lower with dielectric coolants used in electronic cooling.

Another local chip cooling technique is jet impingement cooling. In this technique, a coolant is flown through a small orifice to form a jet. The jet is directed toward the surface of the CPU chip, and can effectively remove large heat fluxes. Heat dissipation of over 1000 W/cm2 has been reported.[36] The system can be operated at lower pressure in comparison to the micro-channel method. The heat transfer can be further increased using two-phase flow cooling and by integrating return flow channels (hybrid between micro-channel heat sinks and jet impingement cooling).

Phase-change cooling

Phase-change cooling is an extremely effective way to cool the processor. A vapor compression phase-change cooler is a unit which usually sits underneath the PC, with a tube leading to the processor. Inside the unit is a compressor of the same type as in a window air conditioner. The compressor compresses a gas (or mixture of gases) into a liquid. Then, the liquid is pumped up to the processor, where it passes through a condenser (heat dissipation device) and then an expansion device to vaporize the fluid; the expansion device used can be a simple capillary tube to a more elaborate thermal expansion valve. The liquid evaporates (changing phase), absorbing the heat from the processor as it draws extra energy from its environment to accommodate this change (see latent heat). The evaporation can produce temperatures reaching around −15 to −150 °C (5 to −238 °F). The gas flows down to the compressor and the cycle begins over again. This way, the processor can be cooled to temperatures ranging from −15 to −150 °C (5 to −238 °F), depending on the load, wattage of the processor, the refrigeration system (see refrigeration) and the gas mixture used. This type of system suffers from a number of issues but, mainly, one must be concerned with dew point and the proper insulation of all sub-ambient surfaces that must be done (the pipes will sweat, dripping water on sensitive electronics).Alternately, a new breed of cooling system is being developed, inserting a pump into the thermo siphon loop. This adds another degree of flexibility for the design engineer, as the heat can now be effectively transported away from the heat source and either reclaimed or dissipated to ambient. Junction temperature can be tuned by adjusting the system pressure; higher pressure equals higher fluid saturation temperatures. This allows for smaller condensers, smaller fans, and/or the effective dissipation of heat in a high ambient temperature environment. These systems are, in essence, the next generation fluid cooling paradigm, as they are approximately 10 times more efficient than single phase water. Since the system uses a dielectric as the heat transport medium, leaks do not cause a catastrophic failure of the electric system.

This type of cooling is seen as a more extreme way to cool components, since the units are relatively expensive compared to the average desktop. They also generate a significant amount of noise, since they are essentially refrigerators; however, the compressor choice and air cooling system is the main determinant of this, allowing for flexibility for noise reduction based on the parts chosen.

Liquid nitrogen

As liquid nitrogen boils at −196 °C (−320.8 °F), far below the freezing point of water, it is valuable as an extreme coolant for short overclocking sessions.In a typical installation of liquid nitrogen cooling, a copper or aluminum pipe is mounted on top of the processor or graphics card. After the system has been heavily insulated against condensation, the liquid nitrogen is poured into the pipe, resulting in temperatures well below −100 °C (−148 °F).

Evaporation devices ranging from cut out heat sinks with pipes attached to custom milled copper containers are used to hold the nitrogen as well as to prevent large temperature changes. However, after the nitrogen evaporates, it has to be refilled. In the realm of personal computers, this method of cooling is seldom used in contexts other than overclocking trial-runs and record-setting attempts, as the CPU will usually expire within a relatively short period of time due to temperature stress caused by changes in internal temperature.

Although liquid nitrogen is non-flammable, it can condense oxygen directly from air. Mixtures of liquid oxygen and flammable materials can be dangerously explosive.

Liquid nitrogen cooling is, generally, only used for processor benchmarking, due to the fact that continuous usage may cause permanent damage to one or more parts of the computer and, if handled in a careless way, can even harm the user.

Liquid helium

Liquid helium, colder than liquid nitrogen, has also been used for cooling. Liquid helium boils at −269 °C (−452.20 °F), and temperatures ranging from −230 to −240 °C (−382.0 to −400.0 °F) have been measured from the heatsink.[37] However, liquid helium is more expensive and more difficult to store and use than liquid nitrogen. Also, extremely low temperatures can cause integrated circuits to stop functioning. Silicon-based semiconductors, for example, will freeze out at around −233 °C (−387.4 °F).[38]Optimization

Cooling can be improved by several techniques which may involve additional expense or effort. These techniques are often used, in particular, by those who run parts of their computer (such as the CPU and GPU) at higher voltages and frequencies than specified by manufacturer (overclocking), which increases heat generation.The installation of higher performance, non-stock cooling may also be considered modding. Many overclockers simply buy more efficient, and often, more expensive fan and heat sink combinations, while others resort to more exotic ways of computer cooling, such as liquid cooling, Peltier effect heatpumps, heat pipe or phase change cooling.

There are also some related practices that have a positive impact in reducing system temperatures:

Thermally conductive compounds

There is much debate about the merits of compounds, and overclockers often consider some compounds to be superior to others. The main consideration is to use the minimal amount of thermal compound required to even out surfaces, as the thermal conductivity of compound is typically 1/20 to 1/400 than that of metal, though much better than air.[39]

Heat-conductive pads are also used, often fitted by manufacturers to heatsinks. They are less effective than properly applied thermal compound, but simpler to apply and, if fixed to the heatsink, cannot be omitted by users unaware of the importance of good thermal contact, or replaced by a thick and ineffective layer of compound.

Unlike some techniques discussed here, the use of thermal compound or padding is almost universal when dissipating significant amounts of heat.

Heat sink lapping

Mass-produced CPU heat spreaders and heatsink bases are never perfectly flat or smooth; if these surfaces are placed in the best contact possible, there will be air gaps which reduce heat conduction. This can easily be mitigated by the use of thermal compound, but for the best possible results surfaces must be as flat as possible. This can be achieved by a laborious process known as lapping, which can reduce CPU temperature by typically 5 °C (9 °F).[40][41]Rounded cables

Most older PCs use flat ribbon cables to connect storage drives (IDE or SCSI). These large flat cables greatly impede airflow by causing drag and turbulence. Overclockers and modders often replace these with rounded cables, with the conductive wires bunched together tightly to reduce surface area. Theoretically, the parallel strands of conductors in a ribbon cable serve to reduce crosstalk (signal carrying conductors inducing signals in nearby conductors), but there is no empirical evidence of rounding cables reducing performance. This may be because the length of the cable is short enough so that the effect of crosstalk is negligible. Problems usually arise when the cable is not electromagnetically protected and the length is considerable, a more frequent occurrence with older network cables.These computer cables can then be cable tied to the chassis or other cables to further increase airflow.

This is less of a problem with new computers that use Serial ATA which has a much narrower cable.

Airflow

The colder the cooling medium (the air), the more effective the cooling. Cooling air temperature can be improved with these guidelines:- Supply cool air to the hot components as directly as possible. Examples are air snorkels and tunnels that feed outside air directly and exclusively to the CPU or GPU cooler. For example, the BTX case design prescribes a CPU air tunnel.

- Expel warm air as directly as possible. Examples are: Conventional PC (ATX) power supplies blow the warm air out the back of the case. Many dual-slot graphics card designs blow the warm air through the cover of the adjacent slot. There are also some aftermarket coolers that do this. Some CPU cooling designs blow the warm air directly towards the back of the case, where it can be ejected by a case fan.

- Air that has already been used to spot-cool a component should not be reused to spot-cool a different component (this follows from the previous items). The BTX case design violates this rule, since it uses the CPU cooler's exhaust to cool the chipset and often the graphics card. One may come across old or ultra-low-budget ATX cases which feature a PSU mount in the top. Most modern ATX cases do however have a PSU mount in the bottom of the case with a filtered air vent directly beneath the PSU.

- Prefer cool intake air, avoid inhaling exhaust air (outside air above or near the exhausts). For example, a CPU cooling air duct at the back of a tower case would inhale warm air from a graphics card exhaust. Moving all exhausts to one side of the case, conventionally the back/top, helps to keep the intake air cool.

- Hiding cables behind motherboard tray or simply apply ziptie and tucking cables away to provide unhindered airflow.

There is little agreement on the effectiveness of different fan placement configurations, and little in the way of systematic testing has been done. For a rectangular PC (ATX) case, a fan in the front with a fan in the rear and one in the top has been found to be a suitable configuration. However, AMD's (somewhat outdated) system cooling guidelines notes that "A front cooling fan does not seem to be essential. In fact, in some extreme situations, testing showed these fans to be recirculating hot air rather than introducing cool air."[42] It may be that fans in the side panels could have a similar detrimental effect—possibly through disrupting the normal air flow through the case. However, this is unconfirmed and probably varies with the configuration.

Computer types

Desktops

Desktop computers typically use one or more fans for cooling. While almost all desktop power supplies have at least one built-in fan, power supplies should never draw heated air from within the case, as this results in higher PSU operating temperatures which decrease the PSU's energy efficiency, reliability and overall ability to provide a steady supply of power to the computer's internal components. For this reason, all modern ATX cases (with some exceptions found in ultra-low-budget cases) feature a power supply mount in the bottom, with a dedicated PSU air intake (often with its own filter) beneath the mounting location, allowing the PSU to draw cool air from beneath the case.Most manufacturers recommend bringing cool, fresh air in at the bottom front of the case, and exhausting warm air from the top rear[citation needed]. If fans are fitted to force air into the case more effectively than it is removed, the pressure inside becomes higher than outside, referred to as a "positive" airflow (the opposite case is called "negative" airflow). Worth noting is that positive internal pressure only prevents dust accumulating in the case if the air intakes are equipped with dust filters.[43] A case with negative internal pressure will suffer a higher rate of dust accumulation even if the intakes are filtered, as the negative pressure will draw dust in through any available opening in the case

The air flow inside the typical desktop case is usually not strong enough for a passive CPU heatsink. Most desktop heat sinks are active including one or even multiple directly attached fans or blowers.

Servers

Rack-mounted

Data centers typically contain many racks of thin, horizontally mounted 1U servers. Air is drawn in at the front of the rack and exhausted at the rear. Because data centers typically contain large numbers of computers and other power-dissipating devices, they risk equipment overheating; extensive HVAC systems are used to prevent this. Often a raised floor is used so the area under the floor may be used as a large plenum for cooled air and power cabling.Another way of accommodating large numbers of systems in a small space is to use blade chassis, oriented vertically rather than horizontally, to facilitate convection. Air heated by the hot components tends to rise, creating a natural air flow along the boards (stack effect), cooling them. Some manufacturers take advantage of this effect.[44][45]